OPC UA Getting Real and Real-time - Report from OPC Day Finland 2018

17.12.2018

OPC Day at Finnish Society of Automation (slides)

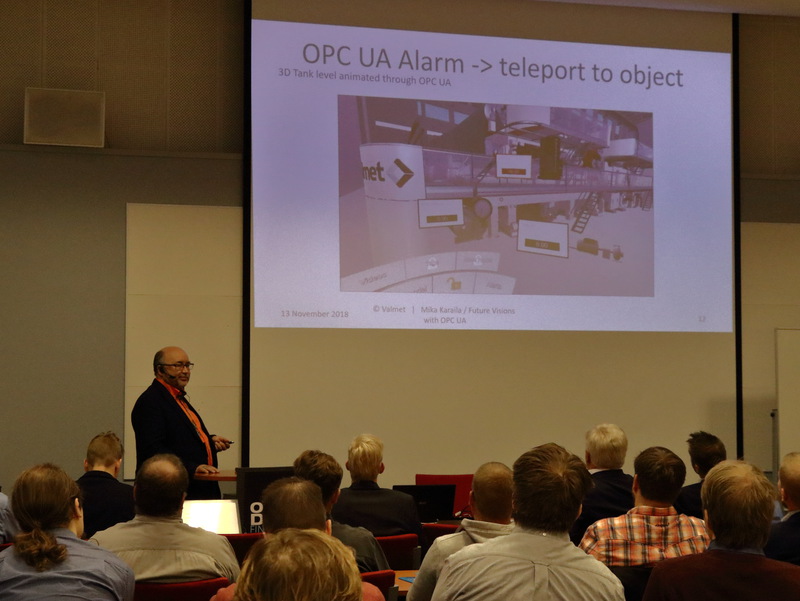

Together with the Finnish Society of Automation, Valmet had the honor of hosting OPC Day Finland 2018 in Tampere. This was the 14th such event arranged on an annual basis that this year had the theme OPC UA Getting Real and Real Time. According to Mika Karaila, Research Director in Valmet’s automation business unit, this is a hot topic for Valmet. With the obvious advantage of being platform independent and secure, OPC UA is bringing all elements together, from edge devices to enterprise planning. With 14 pilots ongoing, the largest of which is with Neste covering 5,000 tags, Valmet’s OPC UA effort is rapidly expanding with the promise of real time communication suitable for process control.

OPC Unified Architecture (OPC UA, IEC 62541) has been selected as the communication protocol of choice for Industrie 4.0 and this OPC Day provided the opportunity for 80 industry professionals to gain the latest insights about the technology, the latest advances and future direction of OPC UA. Alongside the program of technical presentations, sponsors were provided with an exhibition area to further show products and encourage discussion on OPC UA.

Big data, edge devices and interoperability

The day started with a keynote address from Valmet’s Mika Karaila, Research Director, on Future Visions with OPC UA. His presentation covered briefly the history of OPC and the effect of Big Data and cloud computing to the Industrie 4.0 smart factory concept. The next steps with OPC UA are now evolving from information models to the automation systems and beyond.

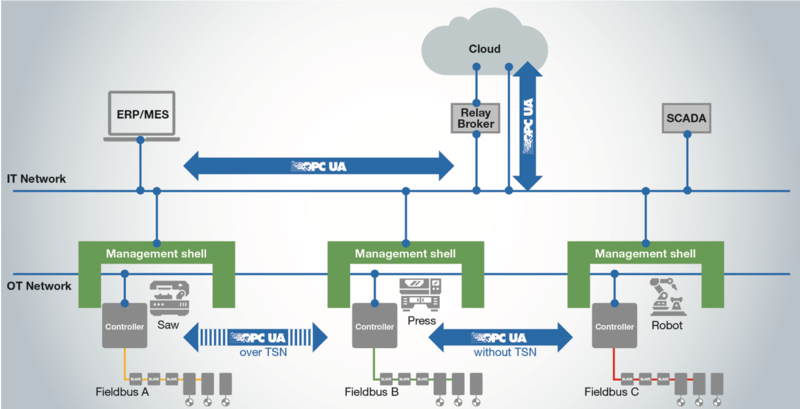

So in future, OPC UA will be providing a seamless architecture from edge devices, including sensors and control devices to enterprise and cloud computing. The challenge is to manage the integration with the growth of the scale and complexity of the systems where Karaila sees the opportunities that OPC UA now offers in interoperability between edge devices and systems from different manufacturers.

From mass to matrix production

In the OPC Foundation keynote, OPC UA Enables Smart Manufacturing, I, Jouni Aro, continued with the development of OPC UA. As manufacturing moves from mass production to matrix production, more individually customized products can be manufactured on a flexible production line. This requires more intelligence to the system design and OPC UA is enabling that in practice.

The German Industrie 4.0 initiative is laying out an architecture for future manufacturing plants. The automotive industry is especially looking for more flexibility in configuring their production lines - which will actually turn from a line to assembly cells in a grid layout, where each product can take an individual route according to the actual order from the customer.

OPC UA is identified as the key technology, enabling both standard communication, but also standard information modeling capabilities. These will enable a plug-and-work framework that can enable fulfilling the above mentioned needs of smart manufacturing.

Then Andreas Faath in his presentation VDMA supports the machinery industry developing OPC UA Companion Specifications detailed the cooperation of VDMA working groups with the OPC Foundation in defining industry needs.

Real Time

As OPC UA extends to edge devices, Achim Laubenstein of the FieldComm Group presented OPC UA and Field Device Integration (FDI) for Industrie 4.0. Whereas earlier as many as 200 files for a relatively simple sensor could be needed for integration, FDI virtualizes physical devices in software as a FDI Device package. FDI brings standardization to the packaging and distribution of all the software and tools with only one FDI Device Package needed for a successful integration with a host.

OPC Foundation had just announced big news that OPC UA is going down to the field level. This announcement was completed a couple of weeks later in a press release where all major automation industry players announced that they are behing this initiative..

So it was great to have Matthias Damm, of ascolab GmbH, the leading figure of this work in OPC Foundation to give us a presentation about OPC UA Technical Update: PubSub Model and Time Sensitive Networks (TSN). Together with an overview and status update of OPC Foundation collaboration with partners, he described the introduction of new working groups to identify, manage and standardize OPC UA relevant topics focused on industrial automation.

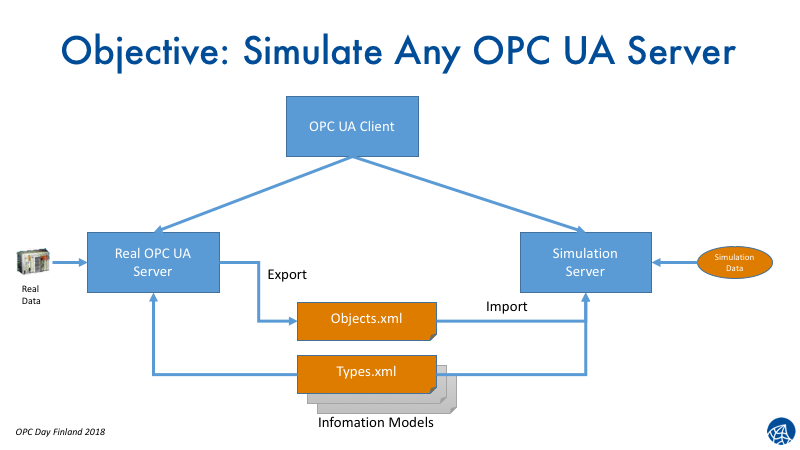

Simulation of OPC UA Information Models

In the Prosys OPC presentation, Lauri Saikko presented the improvements designed for Prosys OPC UA Simulation Server to enable Simulation of OPC UA information models. This will be an interesting addition, enabling address space reflection of real OPC UA servers with simulated data. Stay tuned for new product releases in future!

One of the new information models to use will be OPC UA for Data Exchange in Process Industry (DEXPI) that we have been defining with Nikolaos Papakonstantinou from VTT Finland. DEXPI is a standard for engineering of Piping & Instrumentation (P&I) Diagrams that is driven by end-user companies like BASF and Bayer and supported by CAD/CAE software vendors such as Autodesk, Aveva, Intergraph and Siemens among others.

OPC UA in the Real World

The event gathered more sponsors than any one of the previous events, including key industrial device providers (Beckhoff, B&R, Kepware & Siemens) that have now top level OPC UA products available in the market. This will be the key for enabling end-users to create installations from OPC UA only without the need to go with OPC UA Gateway products.

To highlight the current state of art, Jukka Peltola from Plant4You was giving a talk about his experiences of OPC UA in the Real World. He has been comissioning a new green field factory, where OPC UA was used extensively to implement a highly interconnect production plant using off-the-shelf products from various vendors. Jukka’s experience of practical issues and recommendations are very helpful for anyone that wishes to use OPC UA on large or even small scale.

Matthias Damm presented the upcoming Global Discovery Server of Unified Automation that is expected to be available in 2019. That will be a major component enabling proper site wide security management of OPC UA applications.

Neste Engineering Solutions have been another frequent sponsor of these events. They have created perhaps the most successful OPC UA based product in the world, the NAPCON Suite. NAPCON is an Advanced Process Control platform that is used in petro chemical plants (Neste is the Finnish oil company), but also in other production sites that can benefit from highly optimized production control.

Mika Karaila ended the day by presenting the OPC UA Capabilities of Valmet DNA and the introduction of edge devices with OPC UA exemplified by a Valmet smart consistency transmitter providing data via OPC UA.

Presentations

The recorded video presentations and copies of all the slides are available on the Finnish Society of Automation OPC Day web page. The videos are also available on the YouTube playlist.

Check the Products for more about the Prosys OPC products.

The article was written in co-operation with Nigel Farrand (Latitude61).

Jouni Aro

Chief Technology Officer

Email: jouni.aro@prosysopc.com

Expertise and responsibility areas: OPC & OPC UA product development, project work and customer support

Tags: Events, OPC UA, IoT, OPC Day

comments powered by DisqusAbout Prosys OPC Ltd

Prosys OPC is a leading provider of professional OPC software and services with over 20 years of experience in the field. OPC and OPC UA (Unified Architecture) are communications standards used especially by industrial and high-tech companies.

Newest blog posts

Why Do Standards Matter in Smart Manufacturing?

The blog post discusses the importance of standards in smart manufacturing, envisioning a future where auto-configurable systems in manufacturing rely on standardized data formats for seamless integration and reduced costs, with a focus on the OPC UA standard family as a key enabler.

OPC UA PubSub to Cloud via MQTT

Detailed overview of the demo presented at the OPC Foundation booth

SimServer How To #3: Simulate data changes on a server using an OPC UA client

A two-part step-by-step tutorial on how to write data changes on an OPC UA server using an OPC UA client.